In this post, you will learn what is carburetor and its working principle, and Eight different types of carburetors with their functions.

What is a Carburetor?

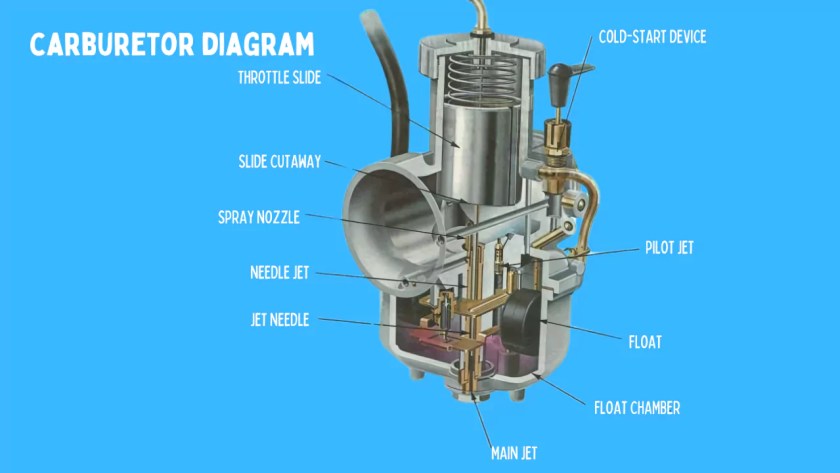

A carburetor is a device for atomizing and vaporizing the fuel and mixing it with the air in varying proportions to suit the changing condition of spark ignition engines. The air-fuel mixture so obtained from the carburetor known as the combustible mixture.

The carburetor is the most important part of the fuel system of spark ignition engines. the carburetor is attached between the fuel filter and the induction manifold. If supplies the air-fuel mixture of varying proportions to suit engine operating conditions.

The liquid fuel enters the float chamber of the carburetor. And the air enters the air horn of the carburetor.

Mixing of the fuel and air takes place when both pass through the venturi in the mixing chamber of the carburetor. This air and fuel mixture then goes to the intake manifold.

Carburetor

The process of mixing the gasoline fuel with air to get the combustible mixture is known as carburetor.

Understanding The Terms Vaporization and Atomization

- Vaporization- It is the change of state of the fuel from liquid to vapor.

- Atomization- It is the mechanical breaking up of the liquid fuel into small particles so that every particle of the fuel is surrounded by air.

To produce quick vaporization of the liquid fuel, it is sprayed into the air passing through the carburetor. Spraying of the liquid turns it into many fine particles so that the vaporization occurs almost instantly.

A carburetor supplies the air-fuel mixture of varying proportions to suit the changing conditions of the engine. The mixture must be rich (have a higher percentage of fuel) for starting, acceleration, and high-speed operation.

The mixtures should be mean (have a lower percentage of fuel) for operation at intermediate speed with a warm engine. The theoretically perfect mixture of air and gasoline contains 15 parts of air and 1 part of gasoline by weight.

An ideal carburetor passes the mixture of completely vaporized fuel and air, in the proper proportion to the intake manifold and cylinder.

But in the present-day carburetors, the complete vaporization of fuel is not achieved, due to the heavy nature of the fuel and other limitations. The heated intake manifold and hot spots in the manifold vaporize part of the atomized fuel.

Even until the end of the compression stroke in the cylinder, the gasoline does not vaporize completely. Although the heat and pressure during the compression stroke are applied to it.

Types of Carburetors

Following are the different types of carburetors:

#1. A Carburetor According to The Arrangement of Float Chamber.

Eccentric Type

In eccentric float chamber types of carburetors, the float chamber is placed at the side of the venturi tube. This type of carburetor does not provide the correct air-fuel mixture when the vehicle is ascending a grade.

Concentric Type

In concentric float chamber types of carburetors, the float chamber is placed around the venturi tube.

Note:

When the vehicle is running on a horizontal road, the level of the gasoline in the float chamber and the discharge jet is normal, as at (A). The carburetor corrects the air-fuel mixture to the engine.

When the vehicle is ascending or descending a grade, the carburetor is tilted and the level of the gasoline changes in the discharge jet as at (b) and (c).

This causes too much or too little gasoline to be supplied by the jet giving incorrect mixtures. The concentric float chamber-type carburetors do not have this difficulty.

The level of the gasoline in the discharge jet remains approximately constant, which provides the correct air-fuel mixture to the engine in all positions of the level.

#2. The Carburetor According to the Direction of Air-Flow.

Downdraft Carburetor

In downdraft carburetor types of carburetors, the air enters the top of the carburetor rector and leaves at the bottom.

Side-draft Carburetor

In a side-draft carburetor type of carburetor, the air enters the top of the carburetor and leaves at the side, as at (b).

Updraft Carburetor

In updraft carburetor types of carburetors, the air enters the bottom or side of the carburetor and leaves at the top.

Semi-downdraft Carburetor

In the semi-downdraft carburetor types of carburetors, the direction of airflow is inclined from top to bottom, as at (d).

Note:

In most passenger cars, the downdraft carburetor is used. In this type of carburetor, gravity assists the flow of the mixture. Thus, the engine sucks it better at lower speeds under load. Higher volumetric efficiency of the engine is achieved.

The location of the carburetor above the engine is more accessible for inspection change or repair. The air entering the carburetor is cooler.

#3. Carburetor According to The Number of Units.

Single Barrel Carburetor

Single barrel carburetor has only one barrel.

Double Barrel Carburetor

Dual-barrel carburetor has two barrels, each containing a fuel jet, venturi tube idling system, choke, and throttle. It may have a single air inlet, choke, and float chamber, although it frequently has two floats one for each jet. It has only an accelerating pump.

Four Barrel Carburetor

Four the barrel, the carburetor is made up of two dual carburetors in one unit. The primary side of a complete dual carburetor contains a choke, an accelerating pump, a power valve, and a complete main metering and idle system.

The secondary unit has one float bowl and a dual carburetor main metering system and idle system.

Note:

Usually, passenger car engines of eight or more cylinders are provided with a dual carburetor having a dual intake manifold.

Each barrel of the dual carburetor feeds one branch of the intake manifold. This arrangement provides uniform distribution of the fuel mixture to the cylinders.

#4. Carburetor According to The Type of Metering System.

Air Bleed Jet Carburetor

In the air bleed jet types of carburetors, the fuel is supplied to the main discharge nozzle through the main metering jet at low speeds.

The air bleeds are connected to a vent tube located inside the main discharge nozzle so that air is mixed with fuel as it is drawn into the carburetor venturi.

As the suction of the main discharge nozzle increases at higher speeds, more air is drawn through the main air bleed, and the correct air-fuel mixture is maintained.

Metering Type Carburetor

In the metering rod types of carburetors, the amount of fuel is controlled by a rod that extends into the jet. The metering rod has three steps of different diameters. Which opens the space in the jet through which the fuel passes.

The metering rod is connected to the throttle shaft by a suitable linkage. so that it is raised when the throttle valve is opened and lowered when the throttle valve is closed.

When the rod is raised, it provides more area between the jet and the rod and more fuel passes to match its flow of air at high speeds.

#5. Carburetor According to the type of Venturi.

- Plain venturi.

- Double venturi

- Vane venturi

- Nozzle-bar venturi

- Triple venturi.

Different types and numbers of venturies are used in the carburetor design, according to which the carburetors are classified. The carburetor may have plain, double, vane, nozzle-bar, and triple venturi.

Each type of venturi is designed to provide the decreased pressure of airflow so that it may draw fuel from the discharge jet. Multiple venturies help to keep the fuel away from the carburetor walls to reduce condensation.

#6. According to the Pressure above the Fuel in the float chamber.

Unbalanced Carburetor

If the pressure above the fuel in the float chamber is atmospheric pressure, the carburetor is said to be unbalanced.

Balanced Carburetor

If the pressure above the fuel in the float chamber equals the air intake in the air horn, the carburetor is said to be balanced.

Note:

The balanced carburetor contains a balance tube and passages that connect the air horn with the top of the float chamber so that the pressure in the air horn and the float chamber remains the same.

In this case, if a clogged air cleaner restricts the air intake, the carburetor’s mixture ratio is unaffected. Also, it prevents the discharge of the fuel through the pump discharging jet at high speeds.

#7. According to the Types of Power System.

Manually Operated Carburetor

In the manually operated carburetor. the power jets for enriching the mixture are operated by mechanical linkage to the throttle shaft.

Vacuum Controlled Carburetor

In a vacuum-controlled carburetor, a vacuum-controlled power jet (called a step-up system) is used to enrich the mixture.

Note:

When the engine is operating normally at cruising speed, with no load, a high vacuum is produced in the vacuum passages connected to the intake manifold.

It pulls the vacuum piston down against the spring so that it holds the step-up rod in the step-up (power) jet to keep it closed.

When the engine is operating on load the intake manifold vacuum falls off, and the spring pushes the piston up which raises the step of the rod out of the jet to allow extra fuel to flow from the float chamber to the discharge nozzle.

The extra fuel supplements the normal supply furnished by the main metering jet. Thus enriching the mixture.

#8. Carburetor According to the method of Varying the Mixture Strength.

Constant Choke Carburetor

In the constant choke carburetor, the mixture strength is determined by the varying depression of a fixed tube or venturi. Solex and zenith carburetors are of this type.

Constant Vacuum Carburetor

In the constant vacuum carburetor, depression in the choke tube is reasonably constant. The size of the jet is varied to provide the correct mixture for all engine operating conditions. S.U. the carburetor is an example of a constant vacuum carburetor.